Smart Drones

Industry

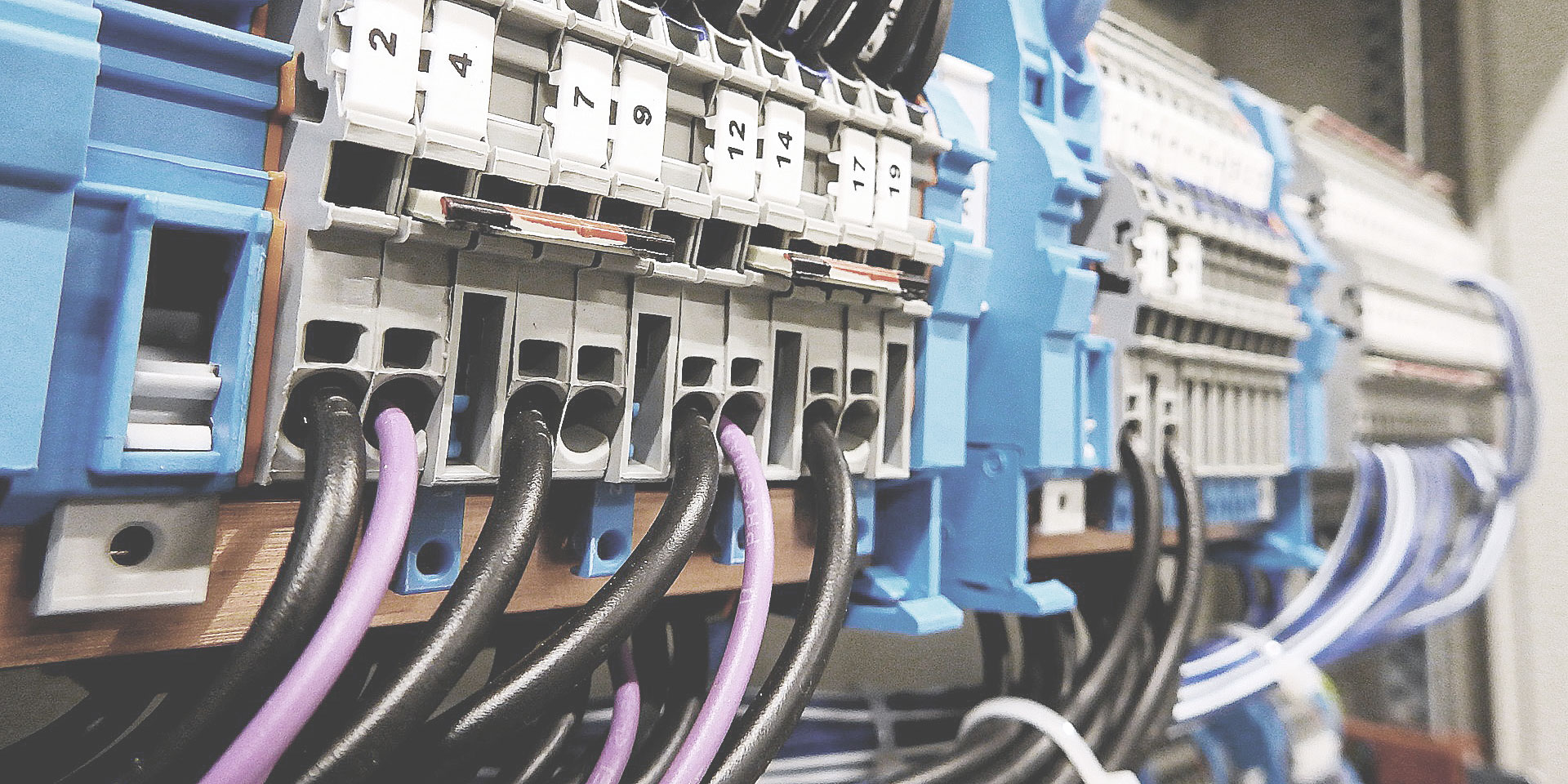

GSD ECABINET

(ELECTRICAL CABINET)

The maintenance of electrical panels must be carried out regularly to ensure safety in the workplace, health of workers and continuity of work processes.

Especially in workplaces, large transformers and electrical panels must be constructed and operated in such a way that they do not cause any damage to life and property in any operating location. These electrical panels and transformers are the most important element that guarantees the safety and control of electricity in a plant.

Panels for distributing electricity to systems used in the business, including electricity meters, capacitors, power contactors, measuring instruments, power relays, control relays, circuit breakers and electrical fuses, should be inspected regularly on an annual basis.

The electrical inspection services performed by GlobsitSmartDrone-ECabinet include testing and control activities. These inspection procedures are designed to minimize potential explosions, fires and similar hazards and to identify the points that will provide energy savings and increase energy efficiency.

GSD- ECabinet summarizes the maintenance, calibration and protection processes of the electrical panel, from the power supply line to the output terminal block of the MV / B transformer through the AI.

Upon detection of the fault, it is therefore possible to easily identify the power line with georeferenced data. Sharp images, obtained through thermal imaging cameras and on-board sensors on Drone, such as NIR, help to effectively communicate the identified problems, so that a series of services can be provided to solve them. Long-range imaging will allow large areas with the correct use of equipment according to IeC regulations.

At the end of the inspection, the collected data will flow into a cloud dashboard, accessible by the customer via PC, tablet and smartphone, and from which it will be possible to download a pdf report and consult the statistics relating to data processing.

GSD FUNNEL

Industrial sectors are particularly attentive to safety and costs. A significant benefit is obtained from the use of SAPR from autonomous flight, that is inspection system on industrial infrastructures with GlobsitSmartDrone FUNNEL.

Our company therefore also operates in the field of inspections on industrial chimneys, with cutting-edge systems in the management of visual data, using drones and software to digitize inspection analysis and to help customers make informed decisions.

Through SmartDrones, equipped with high resolution cameras and thermal sensors such as NIR, we are able to inspect the structures and carry out forecast monitoring; as well as facilitating and simplifying traditional maintenance, significantly reducing costs and improving safety.

Thanks to a cloud platform equipped with Artificial Intelligence, GSD-FUNNEL guarantees careful analysis and the entire management of data in mesh. Our software platform is equipped with an Artificial Intelligence algorithm which, combined with our experience in aerial operations with drones, allows us to view any critical issues found on a 3D model and manage inspections throughout the history of the infrastructure, with the support of detailed visual information necessary to make decisions based on empirical tests according to machine learing training. The production of data flows into personalized reports, download able and accessible from the cloud via PC, tablet and smartphone.

GSD MECTEC

(MECHANICAL COMPONENTS AND MOVEMENT)

GSD-MecTec carries out a series of inspections on the main mechanical components of an industrial plant, with the aim of increasing the safety and reliability of the plants.

Often the breakage of a simple bearing or the blocking of a valve can cause serious damage to machinery or in the worst cases the block of production. In these cases, it is not the cost of the component that worries but the consequences of its possible breakage. The savings therefore consist in avoiding the costs associated with sudden breakages.

Our mechanical inspections are carried out with SmartDrones with thermographic and multispectrographic analysis that allow to detect the mechanical anomaly before any other technique.

Signal recording is a fundamental step to obtain a quality analysis. In fact, it allows us to analyze the mechanical components through a dedicated AI software and which allows us to make a more accurate diagnosis.

It is therefore possible to understand, quickly and without intervening on the system, the status of all types of valves present in the system, whatever the fluid flowing in the pipes.

Knowing the situation of the components is essential for planning maintenance interventions and increasing the reliability and availability of the system.

GSD SECURITY

GlobsitSmartDrone (GSD) – EAGLE and ROVER are two services for the surveillance of large indoor and outdoor areas. The vehicles involved in the operations are totally autonomous and learn to move in ever-changing environments, building a constantly updated map of the environment that surrounds them.

GSD – EAGLE enables patrol and continuous monitoring thanks to the battery management system integrated in the Ground Station. The drone can also be enabled for immediate intervention in case of perimeter alarms, hooking the Ground Station to the pre-existing anti-intrusion system.

GSD – ROVER is able to operate in complete safety thanks to a reliable detection and tracking system for fixed and mobile obstacles. It can be configured for regular patrols as well as for targeted interventions when an alarm gets triggered. The Ground Station controls the operations and acts as a charging station for the vehicle, which will reach it whenever the autonomy is below the safety threshold.

The data collected by the on-board sensors are analyzed by an advanced Computer Vision system. Available features include perimeter management, continuous subject tracking, facial recognition and other customizable options. The thermal data crossed with the day/night visual sensor allow to drastically reduce false positives by certifying the nature of the intrusion and acting accordingly. The systems can work in stealth mode or be configured with audio-visual deterrent tools.

EAGLE – Aerial Inspection & Monitoring

GSD – EAGLE is the smart solution for the inspection and aerial monitoring of large areas. An ultralight drone with visible and thermal payload is able to monitor the area and complete deterrent missions. A single drone is able to cover large areas both day and night in just a few minutes and in totally autonomous mode.

Fully autonomous navigation does not require recurring patterns with fixed GPS waypoints: a dynamic system allows to overcome the problem of tracking patrol patterns making the solution more effective. The drone can be used for the following missions:

• Dynamic patrols

• Verification of alarms triggered by embedded pre-installed sensors

• Audio-visual dissuasion

• Identification of subjects/objects

• Counting subjects/objects

• Tracking subjects/objects

GSD – EAGLE’s stealth flight mode makes surveillance operations discreet and safe. Thanks to an ad-hoc hardware configuration, the drone that performs the service is quiet and can deactivate all the on-board lights.

The Ground Station manages the drone’s missions, provides charge and battery management and communicates with the anti-intrusion systems already installed. To ensure continuous operation of the drone, the Ground Station is equipped with an automatic battery replacement and charging system. All control systems and video streaming are accessible, via Ground Station, over IP.

GSD – EAGLE air operations must be authorized by the competent authorities. The legislation is variable from country to country and when necessary Globsit will provide for the request and the management of the experimental authorizations of the case requested by the authorities in charge.

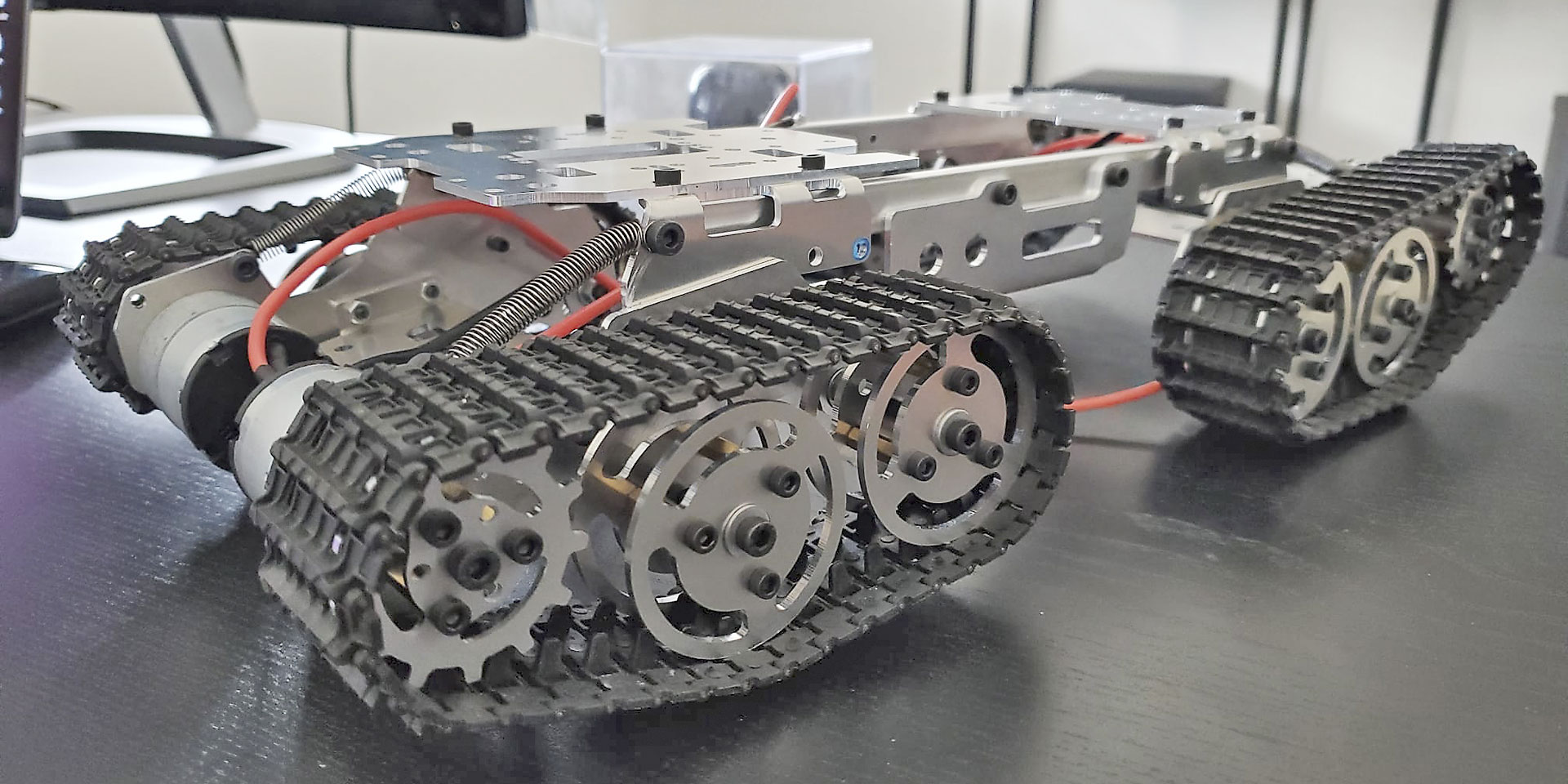

ROVER – Land Inspection & Monitoring

GSD – ROVER is the smart solution for indoor and outdoor terrestrial inspection and monitoring. The system is available in both a rubberised and a tracked variant to best adapt to the operational scenarios. The rover is equipped with advanced sensors and all the collected data are analyzed by a neural network that determines their behavior according to the mission parameters.

The rover navigation is autonomous and does not follow pre-set patterns. A machine learning algorithm ensures the safety of the operations, dynamically mapping the area and integrating in real-time the information coming from all the sensors to identify and track fixed and moving obstacles. The rover can be used for the following day/night missions:

• Dynamic patrols

• Verification of alarms triggered by embedded pre-installed sensors

• Audio-visual dissuasion

• Identification of subjects/objects

• Counting subjects/objects

• Tracking subjects/objects

• Remote controlled interaction with subjects

The GSD – ROVER system is equipped with a Ground Station that manages the rover’s missions and remotizes (over IP) the programming and control. The Ground Station is fixed and also acts as a charging station; the rover will reach it independently as soon as an insufficient charge level is detected. Through the Ground Station it is possible to integrate the pre-installed alarm system with the GSD – ROVER functionalities to maximize the effectiveness of the missions.

Request Information …

By submitting this form you agree to receive email communications from us and agree to your contact details being stored by us.

TOP

HEADQUARTER

GLOBSIT SRL

C.da Chiuse Pere snc

95033 Biancavilla (CT)

ITALIA

P.IVA: 04475230878

Unique Code: M5UXCR1

CONTACTS

Tel. +39 095 981 130

Email: info@globsit.com

PEC: globsit@pec.it

Facebook

Instagram

LinkedIn

Twitter

Youtube

Whatsapp

PAGES

HOME

COMPANY

CYBER SECURITY

SMART DRONES

SCUOLA 4.0

CONTACTS

APPOINTMENTS

POST & NEWS

Privacy & Cookies Policy

CERTIFICATIONS